Sump Tank

DESIGN CONSIDERATIONS

ETS sump tanks are typically used to collect and treat water from drainage collection tanks, oily water runoff and equipment skids. Our Sump tanks come in a range of sizes and configurations to accommodate specific needs. In addition, the tanks are equipped with oil skimmer weir system and oil removal pumps. Coalescing media along with plate packs are available if added efficiency is needed..

When determining flow rate, produced water flow, deck surface area, washdown water, and open/closed drain water must be considered with the respective inlet oil concentrations. These elements are critical in selecting equipment that will achieve your desired effluent. Since sump caissons are designed for intermittent flows, the worst case for operation is used as the basis for design.

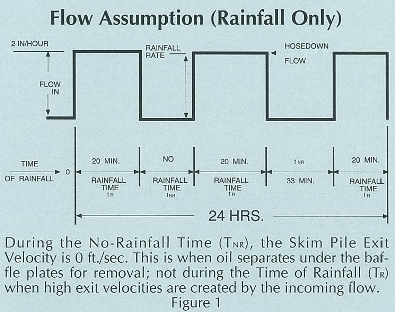

Fig #1, which is based on Gulf of Mexico rain data, sets a scenario where rain or washdown occurs at a rate of 2″ per hour for 20 minute intervals. During this no-rainfall period an exit velocity of 0ft./sec. is observed and the oil separates from the water. The larger the volume of water the greater the volume of oil and the more likely sheen will occur.

Fig #1, which is based on Gulf of Mexico rain data, sets a scenario where rain or washdown occurs at a rate of 2″ per hour for 20 minute intervals. During this no-rainfall period an exit velocity of 0ft./sec. is observed and the oil separates from the water. The larger the volume of water the greater the volume of oil and the more likely sheen will occur.

INLET & EFFLUENT PPM / MICRON CONCENTRATION

INLET & EFFLUENT PPM / MICRON CONCENTRATION

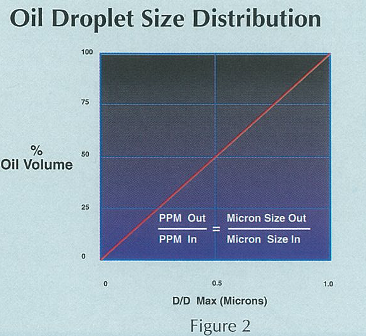

As shown by Fig #2, the relationship between oil droplet size and oil concentration is essential in determining the effectiveness of and oil/water separator. You must calculate the micron size to be removed to achieve your required effluent. It is clear that there will be a distribution of droplets from zero to the maximum size, and this distribution will depend on parameters unknown at the time of the initial design. Experimental data indicates that a conservative assumption for design would be to characterize the distribution in this manner. Oil with a high specific gravity and which is not finely dispersed in the water or is entrained in the water as large droplets will be more likely to cause a sheen. It is also safe to assume that, due to the use of soaps and detergents in deck washdown, much of this “free oil” will be less than 150 micron in size.