Desander

Desanders are used for a wide range of onshore and offshore applications from primary filtration to waterflood injection, disposal wells and SAGD. Units are designed with a two-to-one turn down ratio in most cases with flow rate from 100 bbld to 450,000 bbld per unit.

Desanders are used for a wide range of onshore and offshore applications from primary filtration to waterflood injection, disposal wells and SAGD. Units are designed with a two-to-one turn down ratio in most cases with flow rate from 100 bbld to 450,000 bbld per unit.

The Desander works on a differential of specific gravities of the solid from the liquid. Normally, removing 40 micron and above solids when high (98%+) efficiencies are required. For produced water applications, typical efficiencies are 98% for 74 micron and larger particles, 95% for 73 to 40 micron particles, 84% for 39 to 20 micron particles, and 50% for 19 to 1 micron particles.

Filtration Systems

Filtration Systems

From start to finish- complete filtration systems with specialized accessories to concentrate the solids for easy handling and zero liquid loss as well as sand washing and handling options. Compact designs save space and fit into the toughest piping schemes. Complete systems. Engineered compatibility. Simplified, one-source purchasing.

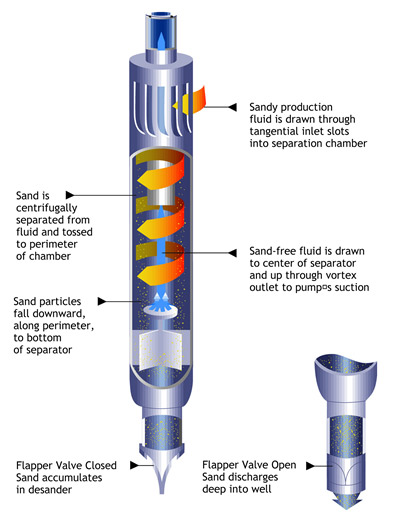

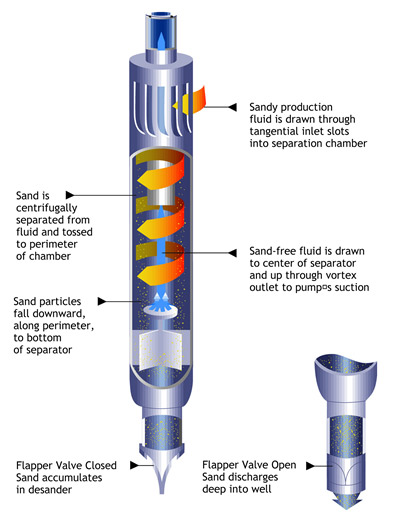

Enerscope Pump Protection Desanders

The downhole desander is designed for ESP and PCP pump protection. These desanders are designed to extend the life and efficiency of your ESPs and PCPs.

The Pump Protection Desander removes sand from the production fluids before they enter the pump. The units can be installed in several configurations in vertical and moderately-deviated oil and gas production wells.

Desanders are Ideal for:

Desanders are Ideal for:

- Brine Filtration

- Disposal Wells

- Downhole Pump Protection for PCP & ESP

- Fire Protection Systems

- Frac Water

- FWKO Protection

- Heat Exchanger Protection

- Offshore Platforms

- Pipeline Flushing & Testing

- Pre-Filtration

- Primary Filtration

- Process Cooling

- Produced Water

- Pump Seal Protection

- SAGD

- Secondary Recovery

- Waterflood Injection Protection

Features & Benefits:

The Enerscope advantage is: no moving parts, minimal to zero liquid loss, and low (0.2-0.8 bar) and steady system pressure drop. For offshore applications, our weight and dimensions are the smallest on the market, making the units very attractive.

Easy installation. Reliable start-up and operation. Dependability you can trust. With decades of proven applications in the oil & gas industry, these products expand on that success with a dedicated line of precision desanders to meet a wide range of flow rates, solids loads and application conditions. Challenge this capability. Benefit from this technology.

Desander Design Features:

- No screens or filter elements to clean or replace; no servicing routines saves maintenance time and cost.

- No backwashing; zero fluid loss options eliminates additional treatment and allows reclaim of valuable fluids.

- Low and steady pressure loss saves energy and provides and more predictable operating system.

- Choice of profiles to accommodate space and piping limitation making for an easy layout and installation.

- Patented Swirlex internal accelerating slots for optimum solids-removal performance.

- Patented internal Vortube for enhanced separation and collection.

- In-line inlet and outlet configuration for simplified piping.

Standard Construction Features:

- ASME code, section VIII, Div I.

- Independently tested.

- ANSI flanged inlet and outlet connections; DIN and other connections available.

- A wide range of standard pressure rating available.

- Carbon Steel construction with special coatings and material available.

- Exterior finish is Powder coated.

Benefits:

- Saves maintenance time & cost: no screens or filter elements to clean or replace.

- Saves energy & provides predictable operating system: low & steady pressure loss.

- Choice of profiles for space & piping limitations: easy layout & installation.

- Optimum solids-removal performance and collection.

- Eliminates additional treatment & allows reclaim of fluids: zero fluid loss options.

Pump Protection Desander Design Features:

- No screens or filter elements to clean or replace; no pulling pump to service saving time and production.

- Low and steady pressure loss saves energy and provides and more predictable operating system.

- Patented Swirlex internal accelerating slots for optimum solids-removal performance.

- Reduces pump wear and extends pump life by four time or more while maintaining optimum pump yield.

- Minimizes critical pump breakdowns.

- Minimum wear offer long life.

- Does not plug or restrict product.

- Saves on pump energy costs with higher operating efficiencies.

Standard Construction Features for Pump Protection Desanders:

- Post-weld heat treated.

- Viton valve.

- EUE treaded connection.

- Glass-blasted finish.

- 316L Stainless Steel construction.

Benefits of Pump Protection Desander:

- Reduces pump wear and extends pump life by four time or more while maintaining optimum pump yield.

- Minimizes critical pump breakdowns.

- Pumps longer for more production.

- Saves on pump energy costs with higher operating efficiencies.

Desanders are used for a wide range of onshore and offshore applications from primary filtration to waterflood injection, disposal wells and SAGD. Units are designed with a two-to-one turn down ratio in most cases with flow rate from 100 bbld to 450,000 bbld per unit.

Desanders are used for a wide range of onshore and offshore applications from primary filtration to waterflood injection, disposal wells and SAGD. Units are designed with a two-to-one turn down ratio in most cases with flow rate from 100 bbld to 450,000 bbld per unit.

The Desander works on a differential of specific gravities of the solid from the liquid. Normally, removing 40 micron and above solids when high (98%+) efficiencies are required. For produced water applications, typical efficiencies are 98% for 74 micron and larger particles, 95% for 73 to 40 micron particles, 84% for 39 to 20 micron particles, and 50% for 19 to 1 micron particles.

Filtration Systems

Filtration Systems

From start to finish- complete filtration systems with specialized accessories to concentrate the solids for easy handling and zero liquid loss as well as sand washing and handling options. Compact designs save space and fit into the toughest piping schemes. Complete systems. Engineered compatibility. Simplified, one-source purchasing.

Enerscope Pump Protection Desanders

The downhole desander is designed for ESP and PCP pump protection. These desanders are designed to extend the life and efficiency of your ESPs and PCPs.

The Pump Protection Desander removes sand from the production fluids before they enter the pump. The units can be installed in several configurations in vertical and moderately-deviated oil and gas production wells.

Desanders are Ideal for:

Desanders are Ideal for:

- Brine Filtration

- Disposal Wells

- Downhole Pump Protection for PCP & ESP

- Fire Protection Systems

- Frac Water

- FWKO Protection

- Heat Exchanger Protection

- Offshore Platforms

- Pipeline Flushing & Testing

- Pre-Filtration

- Primary Filtration

- Process Cooling

- Produced Water

- Pump Seal Protection

- SAGD

- Secondary Recovery

- Waterflood Injection Protection

Features & Benefits:

The Enerscope advantage is: no moving parts, minimal to zero liquid loss, and low (0.2-0.8 bar) and steady system pressure drop. For offshore applications, our weight and dimensions are the smallest on the market, making the units very attractive.

Easy installation. Reliable start-up and operation. Dependability you can trust. With decades of proven applications in the oil & gas industry, these products expand on that success with a dedicated line of precision desanders to meet a wide range of flow rates, solids loads and application conditions. Challenge this capability. Benefit from this technology.

Desander Design Features:

- No screens or filter elements to clean or replace; no servicing routines saves maintenance time and cost.

- No backwashing; zero fluid loss options eliminates additional treatment and allows reclaim of valuable fluids.

- Low and steady pressure loss saves energy and provides and more predictable operating system.

- Choice of profiles to accommodate space and piping limitation making for an easy layout and installation.

- Patented Swirlex internal accelerating slots for optimum solids-removal performance.

- Patented internal Vortube for enhanced separation and collection.

- In-line inlet and outlet configuration for simplified piping.

Standard Construction Features:

- ASME code, section VIII, Div I.

- Independently tested.

- ANSI flanged inlet and outlet connections; DIN and other connections available.

- A wide range of standard pressure rating available.

- Carbon Steel construction with special coatings and material available.

- Exterior finish is Powder coated.

Benefits:

- Saves maintenance time & cost: no screens or filter elements to clean or replace.

- Saves energy & provides predictable operating system: low & steady pressure loss.

- Choice of profiles for space & piping limitations: easy layout & installation.

- Optimum solids-removal performance and collection.

- Eliminates additional treatment & allows reclaim of fluids: zero fluid loss options.

Pump Protection Desander Design Features:

- No screens or filter elements to clean or replace; no pulling pump to service saving time and production.

- Low and steady pressure loss saves energy and provides and more predictable operating system.

- Patented Swirlex internal accelerating slots for optimum solids-removal performance.

- Reduces pump wear and extends pump life by four time or more while maintaining optimum pump yield.

- Minimizes critical pump breakdowns.

- Minimum wear offer long life.

- Does not plug or restrict product.

- Saves on pump energy costs with higher operating efficiencies.

Standard Construction Features for Pump Protection Desanders:

- Post-weld heat treated.

- Viton valve.

- EUE treaded connection.

- Glass-blasted finish.

- 316L Stainless Steel construction.

Benefits of Pump Protection Desander:

- Reduces pump wear and extends pump life by four time or more while maintaining optimum pump yield.

- Minimizes critical pump breakdowns.

- Pumps longer for more production.

- Saves on pump energy costs with higher operating efficiencies.