Description:

- Category:

- Products

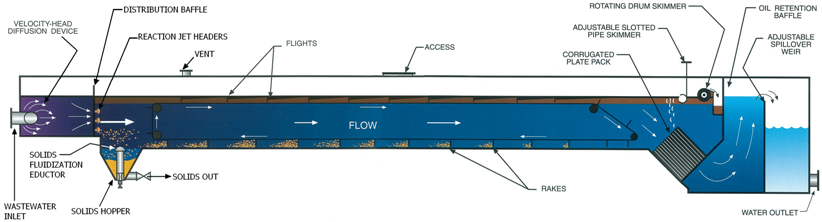

An API-421 Oil in Water Separator is a channel system designed to provide quiescent flow conditions. The quiescent flow conditions created by the separator allow the free oil to rise toward the water surface then coalesce into a separate oil phase above the liquid to be processed.

API-421 Gravity Separator

The Enviro-Tech Systems API 421 Separator is an atmospheric horizontal vessel designed and built for free oil and solids removal.

Principle Of Operation

Oily water and solids will enter the API 421 separator via a pre-separator for flow equalization and collection of bulk oil, trash, and grit. The flow exits the separator forebay and is reduced to laminar flow as it passes through a distribution plate. The distributed flow then enters into each of the API Separator’s bays via gateways, where free oil, solids, and sludge are separated using Stoke’s Law. Solids and sludge will settle to a sludge storage hopper directly under the inlet chamber. As the oily water flows through the separator, oil and solids will continue to separate. A flight skimmer mechanism pulls oil toward the skimmer and moves any solids that settle to the bottom of the vessel in the reverse direction, toward the sludge collection area. Simultaneously, free oil migrates to a collection surface at the interface and will form a thick layer of oil which will, due to flow, move toward the opposite end of the vessel for removal by a skimmer device. Water is then forced through the plate pack (optional) which separates oil droplets smaller than 50 microns. As processed water exits the plate pack, it spills over an adjustable weir into a discharge compartment for retrieval and further processing.

Flight & Rake System

This mechanism provides for oil and solids collection and removal. The system is designed to cover the entire length of the vessel and to remove oil collected at the surface while simultaneously removing solids collected at the bottom of the tank. As long as flow is entering the vessel, the system is designed to run continuously. The flight and rake assembly is comprised of a non-metallic collector chain, fiberglass flights, and UHMW filler blocks and wear shoes. The drive units is an explosion proof motor and located outside the vessel walls.

Please click here to request more information.

Plate Packs (PLPK)

By introducing optional plate packs into the separator, removal efficiency can be increased.

(Please click here to review the different types of plate packs or coalescing media.)

Adjustable Weir System (AWS)

This system allows the user to adjust, up to 4 inches depending on the operating level, the spillover point within the separator.

Rotating Pipe Skimmer (RPS)

The ETS Rotating Pipe skimmer (RPS) provides additional removal of oil in the API-421 separator. The assembly consists of a pipe running transverse across the vessel with slots to allow for surface oil to collect within the pipe. The point of collection, or spillover, can be adjusted externally from the vessel and allows for 150 degrees of rotation. Oil collected is then removed from the pipe by means of an oil recovery system.

Rotating Drum Skimmer (RDS)

The ETS Rotating Drum Skimmer (RDS) comes complete with scraper and oil collector. The system is mounted inside the vessel on a bearing system allowing for smooth rotation. The collector blade removes oil collected on the drum for removal by the oil recovery system.

Rotating Wiper System (RWS)

The ETS Rotating Wiper System (RWS) is ideally suited for applications with suspended solids and froth that would not float into a normal skimmer system or over a weir for removal. The rubber wiper blades turn continuously 360 degrees to force the suspended solids and froth towards a removal system.